Ultrasonic CA Room Cold Storage Doors For Fruit Vegetable Sterilization

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Condition | New | Dimension(l*w*h) | Customized Size |

|---|---|---|---|

| Warranty | 1 Year | Power(w) | Cold Room Specifications |

| Certification | ISO9001 | Product Name | Electric Cold Storage Sliding Door |

| Highlight | Ultrasonic CA Cold Room Door,Fruit Vegetable Sterilization Freezer Room Door,Waterproof Panel Cold Room |

||

![]()

![]()

![]()

![]()

Composition of the controlled atmosphere reservoir: the controlled atmosphere reservoir is a comprehensive system optimization control process.The controlled atmosphere storage is generally composed of storage enclosure, thermal insulation, air tight treatment, controlled atmosphere system, refrigeration system, humidification system, pressure balance system and automatic detection and control system for temperature, humidity, O2 and CO2 gas.The controlled atmosphere storehouse not only requires good heat insulation to reduce the impact of external heat on the temperature in the storehouse, but also requires good air tightness to reduce or eliminate the pressure of external air on the gas components in the storehouse, so as to ensure that the gas components in the storehouse can be adjusted quickly and have a small fluctuation range, so as to improve the quality of fruit storage, reduce the storage cost and prolong the storage time.

The controlled atmosphere reservoir is mainly composed of an insulating layer and an air tight layer.

- Installation process of warehouse body

Now the ground is set out according to the size of the warehouse, then the corner seal is fixed with steel nails, and the warehouse plate is fixed on the corner seal with pull rivets. Before fixing, measure its verticality with a level ruler (or use a laser instrument), and the verticality should be controlled within two thousandths (except if the civil wall is larger than three).

During installation, the coaming shall be installed first. A bolt shall be fixed every 0.6m to 0.8m in the height of the controlled atmosphere storage. After the peripheral plate is installed, the partition plate and the top plate shall be installed at the same time.At the installation position of the top plate, 3cm gap shall be reserved at each side for future foaming and joint filling.After the top plate is installed, the corners shall be covered with external corner seals.Cover the spacer plate with a cover plate and rivet holes to facilitate foaming.The inner corner seal shall be riveted at the same time when installing the partition and top plate.The distance between pull rivets is 20-30cm.

- Airtight treatment

The air tight treatment method at the connection of the storage plate adopts the method of three glues and two cloth, that is, brush the air tight glue three times and stick two layers of non-woven cloth.

The airtight adhesive adopts the special sealant for the air conditioning warehouse, which is developed from special materials. The airtight adhesive is tasteless, non-toxic, non moldy, high and low temperature resistant, and the width of the non-woven fabric is 70mm.

Apply a layer of non-woven fabric after applying a layer of air tight adhesive to the gap between color steel plates, then apply a layer of air tight adhesive, then apply a layer of non-woven fabric, and then apply the last layer of air tight adhesive.

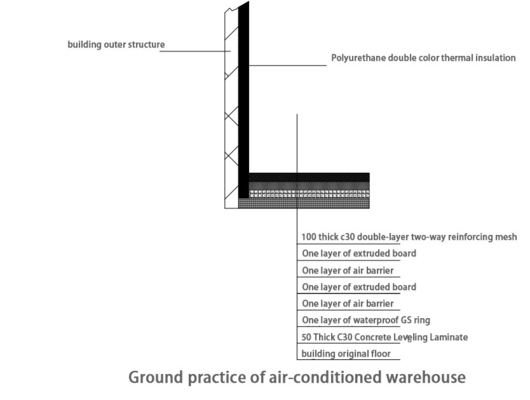

1)Construction scheme for ground waterproof, thermal insulation and air tightness

① Polyethylene polypropylene waterproof coiled material (GS) shall be laid, and the laying layer shall be overlapped by 10cm. GS shall be laid to 20cm ~ 30cm above the vertical plate, and then the corners shall be painted with air tight adhesive, with two layers of adhesive and one layer of non-woven fabric.

② Add 0.15mm black gas barrier film, turn the gas barrier film up about 20cm ~ 30cm at the edge, position it with adhesive tape, and then apply air tight adhesive at the connection.

③ After 12 hours, begin to lay XPS insulation board (extruded board).The insulation board shall be spliced tightly. If the gap is too large, it can be filled with broken materials and then sealed with adhesive tape.

④ After drying, the second layer of thermal insulation and gas barrier film shall be paved. The method is the same as that of the first layer, and the edge shall be turned up by 20cm ~ 30cm.

⑤ Party A shall make a 20mm cement mortar protective layer and then 100mm steel concrete floor.When the cement floor is hardened, the refrigeration drainage pipeline and the humidifier water pipeline shall be paved at the same time.The ground construction is shown in the following figure

![]()

2)Installation of air control room door

The pneumatic control valve is installed on the insulation board and fixed with penetrating nylon bolts. The verticality must be mastered during the installation of the pneumatic control door frame. Otherwise, the opening and closing of the door will be hindered. During commissioning, the bottom rubber strip when the door is lifted is about 1-2mm from the ground. The connection between the blind opening of the door slide and the bottom rail of the door must be about 1cm lower than the door slide rail.

![]()

![]()

3)Project case of controlled atmosphere storage

The following are the projects completed in the past three years. Since there are many application projects, please consult the company for more information

| Serial number | Customer name | entry name |

| 1 | Dingtao County, Heze City, Shandong Province | 1000Ton fruit controlled atmosphere storage project |

| 2 | Shandong Laizhou Xiyuan seedless grape professional cooperative | 1000Ton fruit and vegetable controlled atmosphere fresh keeping warehouse project |

| 7 | Dingyuan Fengwei grain and Oil Trade Co., Ltd | 700T fruit fresh-keeping controlled atmosphere fresh-keeping warehouse project |

| 8 | Pingdu City, Qingdao | 10000t fruit and vegetable controlled atmosphere fresh keeping warehouse project |

| 9 | Yantai Laizhou | 1500 M2 fruit and vegetable controlled atmosphere fresh keeping warehouse project |

| 10 | Linyi, Shandong | 2000square meter |

| 1 | Yu County, Zhangjiakou, Hebei | 600t fruit controlled atmosphere storage project |

| 2 | Dayangshu Town, Hulunbuir | 1200 ton fruit and vegetable controlled atmosphere fresh keeping warehouse project |

| 3 | Dali County, Weinan City, Shaanxi Province | 5000 ton fruit and vegetable air conditioning cold storage project |

| 4 | Da'an City, Jilin Province | 3000 ton modified atmosphere fresh keeping project of fruits and vegetables |

| 5 | Xuzhou Tianlida construction and Installation Engineering Co., Ltd | 600t fruit controlled atmosphere fresh keeping warehouse project |

| 6 | Ganhe farm, Inner Mongolia | 1000 ton modified atmosphere fresh-keeping warehouse project for vegetables |

| 7 | Dingyuan Fengwei grain and Oil Trade Co., Ltd | 7000 ton fruit fresh-keeping modified atmosphere fresh-keeping warehouse project |

| 8 | Pingdu City, Qingdao | 1000 ton fruit and vegetable controlled atmosphere fresh keeping warehouse project |

| 9 | Yantai Laizhou | 1500 M2 fruit and vegetable controlled atmosphere fresh keeping warehouse project |

| 10 | Inner Mongolia Linhe 2 project | 5000t fruit and vegetable controlled atmosphere preservation project |

| 11 | Jining Taibai Taoyuan autumn peach storage base | 2000t fruits and vegetables controlled atmosphere preservation project |

| 12 | Qingdao Pingdu Jinxin Qingyuan | 1500t fruits and vegetables controlled atmosphere preservation project |

| 13 | Linyi Yinan zhujialin warehousing logistics | 25000t fruits and vegetables controlled atmosphere preservation project |

| 14 | Jinan Jiyuan agricultural trade wholesale market | 20000T fruits and vegetables controlled atmosphere preservation project |

Air conditioning system

1)Design scheme of air conditioning system

The controlled atmosphere reservoir shall meet the required gas composition and remain relatively stable. In addition to the required air tight reservoir, there shall also be a system composed of corresponding gas regulating equipment, pipelines and valves, i.e. the controlled atmosphere system.The whole air conditioning system includes gas removal system, carbon dioxide removal system, sterilization, humidity and gas composition automatic analyzer, etc.

![]()

2)Description of equipment configuration for controlled atmosphere storage

Note: the equipment parameter design in this proposal mainly refers to the following points:

① The oxygen reduction time of the single room storehouse should be less than the fruit warehousing cycle, and the air tightness of the storehouse body may decline in the future.

② Fully automatic regulation of oxygen and carbon dioxide components in the warehouse.

③ Air conditioning control range: oxygen 3-21%, carbon dioxide 1.5-5%.

Part II configuration of air conditioning equipment

The equipment parameter design in this proposal mainly refers to the following points:

- ① The oxygen reduction time of the single room storehouse shall be less than the fruit warehousing cycle, and the air tightness of the storehouse may decrease in the future

- ② Fully automatic regulation of carbon dioxide components in the warehouse

- ③ Air conditioning control range: oxygen 3-21%, carbon dioxide 1.5-5%

Main air conditioning equipment

1, Integrated air conditioning machine (main function: oxygen reduction and nitrogen generation control, carbon dioxide pic automatic control)

Features: all of them are assembled by imported European main engines and domestic ones.Carbon molecular sieve filler can reduce the oxygen content in the silo to less than 5%, saving 50% energy compared with similar products.The whole system adopts closed-circuit circulation, without energy loss, and timely adds an appropriate amount of gas to the warehouse to ensure the pressure balance inside and outside the warehouse, which is energy-saving and efficient.

System configuration: * Zhongde vacuum pump

*Shanghai Sanye fan

*German Siemens PLC controller, Danfoss frequency converter

Model: cad-400b

Electric power: 3.5kw/h

Voltage: 380V

Volume: (length, width and height) 2000*1000*2000mm

Number: 1

Quantity: 1 set of pneumatic control valve

Full automatic air distribution station qf-1 quantity: 3rooms need . less than 3room no need

![]()

Function: pneumatic control valve, equipped with American differential pressure controller (Honeywell).

2, 1 set of balance bag

![]()

The function of the balance bag and the micro pressure imbalance will occur during the operation of the controlled atmosphere reservoir. The function of the balance bag is to eliminate or alleviate this micro pressure imbalance.

3, Dry safety valve

![]()

It can protect the reservoir from damage due to the change of positive and negative pressure. It will open automatically when the positive and negative pressure is 12mm water column, and will close automatically when the pressure is lower than 12mm water column. The dry-type safety valve can effectively prevent the water in the water safety valve from being ejected or sucked in due to the change of positive and negative pressure, and also avoid the cold freezing due to the weather,Thus, the manual labor of frequent inspection by operators is greatly saved.It truly realizes the safe operation under the condition of no one on duty.

Fruit and vegetable sterilizer kd-30 (ozone disinfection)

![]()

System configuration: * ozone generator

*Damp proof fan

Electric power: 0.7kw/h

Voltage: 220V

Volume: (length, width and height) 350*600*600mm

Quantity: 1 set

Function: the fruit and vegetable sterilizer is used to kill virus and remove ethylene. In fact, ozone and negative ions are used to remove ethylene and sterilize.

System composition of fruit and vegetable sterilizer:

Electrostatic spraying shell

Epoxy encapsulated power module (UFC, HFC)

High pressure reaction tube

Totally enclosed fan

Electrical automatic control

working principle:

The electronic power frequency oscillation (the oscillation frequency is 100Hz) is used to form a high-voltage corona in the generator and generate ozone and negative ions by air electrolysis. The ozone and negative ions are blown out by the fan, so as to achieve the purpose of fresh-keeping of fruits and vegetables.This machine has unique design, simple maintenance, high humidity resistance and low temperature resistance. It is the best choice for fruit and vegetable controlled atmosphere storage industry.(the control mode includes manual control and microcomputer time control.)

Role of ozone:

Ozone is characterized by sterilization and moisturizing.It has solved various problems caused by long-term storage in the cold storage in industry, such as early ripening, production of spoilage pathogens, water loss and so on. Even under the ordinary cold storage conditions, the fruit quality, freshness and environmental cleanliness can be maintained for 7-8 months.The molecular formula of ozone is O3, which is oxidizing and has stronger bactericidal ability than chlorine. O3 is very easy to decompose: O3 → O2 + O, its decomposition product o is unstable and is an environmental freshener.

Ozone is regarded as a green and pollution-free product by the world.

Ozone inhibits the respiration of fruits and vegetables and reduces nutrient consumption.Generally, the production of ozone is accompanied by the generation of negative ions. When they work together, they will significantly reduce the metabolic activity of fruits, reduce water loss and nutrient consumption, and maintain the freshness and flavor of fruits.

Degrade and eliminate harmful gases such as ethylene, and form microbial inhibitors such as mold.Ozone is a strong oxidant, which can degrade the organic oxygen, organic phosphorus and other pesticide residues on the surface of fruits and vegetables. In the fruit and vegetable storage, ozone treatment can eliminate the ethylene (ripening agent), acetaldehyde, ethanol and other harmful gases released by the respiration of fruits and vegetables, so as to reduce the respiration of fruits,The intermediate oxides in the chemical reaction between ozone and ethylene are also effective inhibitors of microorganisms such as molds.

Inhibit and kill germs, prevent rot and mildew.The decay of fruits and vegetables is generally caused by microbial bacterial erosion.Use the strong sterilization ability of ozone to eliminate chloromycetes, spores, penicillins and bacilli, as well as black stalk rot and soft rot.

Ultrasonic humidifier kfd-18 (humidification)

![]()

System configuration: * heating and humidity measurement

*Damp proof fan

Electric power: 0.8kw/h

Voltage: 220V

Volume: (length, width and height) 350*550*850mm

Quantity: 1 set

The ultrasonic humidifier of the controlled atmosphere storage is specially designed for the controlled atmosphere cold storage. It is a closed circulating type. The humidification will not affect the pressure and gas composition in the storage.Independent water tank design, independent water tank water temperature control, will not affect the atomization amount due to the water temperature change of the atomizer.In addition, the independent water tank will not condense or drip due to the temperature difference inside and outside the water tank.The moisture-proof fan is vacuum coated, which is truly waterproof and moisture-proof.The latest ultrasonic atomization technology, the latest energy gathering technology.The machine is made of 1.2 iron plate cutting and bending line, which ensures the strength of the humidifier as an industrial product. It can be installed in various ways, such as side hanging, ceiling and floor mounting.The humidification capacity of 9-18 kg per hour is automatically controlled by temperature sensor and time sequence, and the low-temperature compensated constant temperature heating is realized under the fully sealed working environment through the function of moisture-proof fan.In addition, the independent water tank will not condense or drip due to the temperature difference inside and outside the water tank.The moisture-proof fan is vacuum coated, which is truly waterproof and moisture-proof.The latest ultrasonic atomization technology, the latest energy gathering technology.The machine is made of 1.2 iron plate cutting and bending line, which ensures the strength of the humidifier as an industrial product. It can be installed in various ways, such as side hanging, ceiling and floor mounting.

All In One Air Machine

Automatic Air Distribution Station

Fruit And Vegetable Sterilization Machine

Automatic Ultrasonic Humidifier

Safety Valve

Air Balance Bag

Air Compressor

Air Control Door

![]()

![]()

![]()

![]()